The Low Cost, High Volume Dewatering Solution

TenCate Geotube® dewatering containers are an effective dewatering technology fabricated from a specially engineered textile which provides confinement of the fine solids inside the container, while allowing water to permeate through the engineered textile. As the water drains, the solids continue to densify and consolidate over time. Once the solids are fully consolidated or have met minimum requirements for transport, several options are available for disposal of the dewatered material.

Geotube® dewatering containers are prefabricated using high strength and quality seaming techniques into tubular, bag-like, or other forms with filling ports or other provisions for site filling. The containers are custom sized to save land space and are ideal for areas where space is a constraint. Geotube® dewatering containers are designed to optimize the solids retention and effluent discharge rate and quality making it a highly efficient and environmental friendly solution for various sludge dewatering applications.

Visit our dedicated TenCate Geotube® Dewatering Website

The benefits of TenCate Geotube® Dewatering containers at a glance:

- Highly effective technology that produces high volume reduction and retention of solids

- High effluent discharge rate with clear filtrate that can be recirculated through the system

- Custom-sized containers saves expensive and limited land space

- Easy removal and disposal of solids

- Efficient, versatile and environmental friendly solution reduces carbon footprint

- Reliable in all weather conditions and reduces risks in operational safety

- Cost effective, low maintenance and saves time

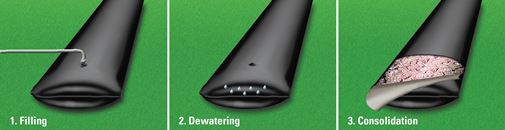

How TenCate Geotube® Dewatering Technology Works?

Dewatering with TenCate Geotube® technology is a three-step process:

Step 1: Filling

Sludge (slurry material) is pumped into the TenCate Geotube® container. Environmentally-safe polymers are added to the sludge, which makes the solids bind together and water separate. The TenCate Geotube® container's unique fabric confines the fine grains of the material.

Step 2: Dewatering

Clear effluent water simply drains from the TenCate Geotube® container through the small pores in the specially engineered textile. This results in effective dewatering and efficient volume reduction of the contained materials. The volume reduction allows for repeated filling of the TenCate Geotube® container. Over 99% of solids are captured, and clear filtrate can be collected and recirculated through the system. The decanted water is often of a quality that can be reused/returned for processing or returned to native waterways without additional treatment.

Step 3: Consolidation

After the final cycle of filling and dewatering, the solids remain in the bag and continue to densify due to desiccation as residual water vapor escapes through the fabric. Volume reduction can be as high as 90 percent. When full, the TenCate Geotube® container and contents can be deposited at a landfill, remain on-site, or the solids can be removed and land-applied when appropriate.

Typical TenCate Geotube® Dewatering Applications

?w=16&h=9&action=crop)

Contact us

If you have any more questions about TenCate Geotube® Dewatering, please contact us.

We are pleased to help you in designing, installing our solutions. Contact your local TenCate Geosynthetics partner

.jpg?w=16&h=9&q=1)

.jpg?w=16&h=9&q=1)